Build new products based on AI and IoT technologies.

Challenge:

The company produces sea dampers for the marine industry. They want to innovate their product including IoT technology.

Other Requirements:

- Scalability;

- Low maintenance requirements;

- Edge software deployment must be supported by platforms that allow the necessary updates or applications of patches automatically;

- Edge hardware must be designed for critical environments: low energy, high resistance to shock, vibration, temperature, etc.

Industry Sector:

IIoT

Challenge classification:

Smart products

Time for Project Completion:

3 months

____

Preliminary Analysis:

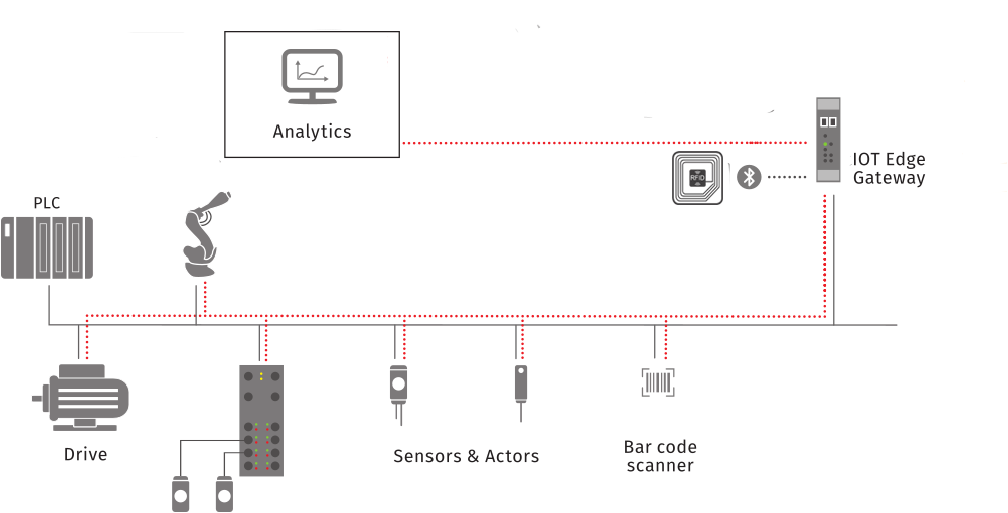

The final choice of the solution is based on the comparison made before, the industry’s requirements and the answers to the questions asked. Initially, we chose the architecture of the edge layer. Regarding the industry requirement that edge hardware has to be designed for critical environments, both solutions satisfy it. However, the fact that the factory consists of legacy industrial components prevents us from choosing the first solution as the existing controllers do not have the necessary processing capabilities to integrate edge computing inside them. Also, the enterprise does not want to replace its controllers due to reliability concerns and vendor restrictions. Another reason that prevents us from adopting the first solution is the requirement not to stop the system’s operation. A loss of control can lead to serious safety threats, unacceptable productivity losses, unexpected downtimes, and behavior. So to achieve networking on the shop floor, it is recommended to use IIoT Edge Gateways.

____

Solution Summary:

Based on the analysis made in the previous two sections, the following solution is proposed:

The solution allows us to collect data from different industrial units like sensors, PLCs, and industrial engines and run applications such as event processing, predictive analytics, and machine learning models closer to the data sources (i.e. on edge). This solution reduces latency since the data does not have to be sent back and forth to the cloud, thus ensuring real-time responsiveness of the manufacturing process. In addition, the proposed solution employs RFID tags and readers for optimizing various industrial operations. Finally, blockchain technology is exploited to create a secure and immutable database of assets or products.

Additional Benefits:

- Faster response time.

- Operational Efficiency.

- Enhanced Security.

- Interoperability between legacy and modern devices.

Possible Difficulties:

- Edge networks are not simple to build and can be expensive.

- The edge device may be directed to discard information to save costs.

- Most production facilities cannot keep temperature and humidity levels within the acceptable ranges for reliable IT equipment performance. IT equipment protection also necessitates dust-protected or sealed IT racks or enclosures that prevent unfiltered outside air from accessing the equipment and dedicated cooling.