Monitor and improve the efficiency of production processes.

Challenge:

Forecast of maintenance duration for production tools: Each incoming tool is inspected before the maintenance and repair activities begin. This is done by skilled workers. The inspection results are documented according to specific levels for certain specific categories (condition of paint, dirt, missing parts, etc.). To document the condition of incoming equipment photos are taken by the worker. In order to reduce the effort for inspection and enable even non-experienced workers to conduct this task it is intended to semi-automate the inspection activity by using photos of the incoming assets and to determine their condition automatically.

Industry Sector:

Provider and integrator of solutions for manufacturing and logistics

Challenge classification:

Real-time process monitoring and optimization; Smart planning and scheduling of processes.

Time for Project Completion:

6 months

____

Preliminary Analysis:

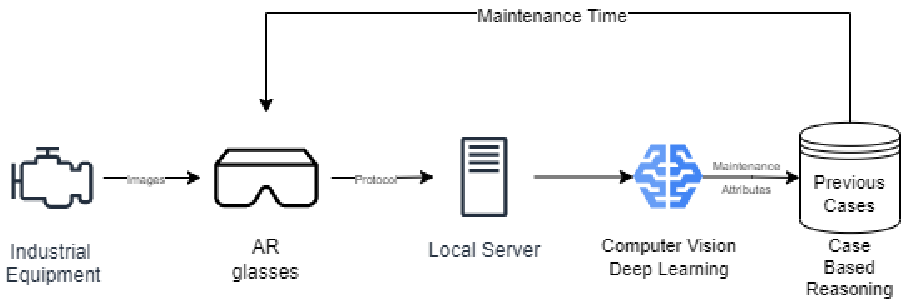

The final choice of the solution is based on the comparison made before, the industry’s requirements and the answers to the questions asked. Initially, we chose the computation platform (local server or Cloud-based server or local device) in which the AI-powered system will be developed. For the proposed solution to remain reliable even in the case of lack of connectivity or limited connectivity, we have to choose between a local server or an embedded device where the images of the failed production tool are collected and used to estimate maintenance duration. For this choice, the fact that the system is not Cloud-ready also played a role as the networking of the manufacturing ecosystem requires enough time. Although mobile devices have become more powerful to handle computations near real-time, the need to use a central database led us to decide not to use embedded systems but a local server/data center.

Regarding the interaction, it is suggested to use Augmented Reality technology because non-skilled workers can operate the system without needing to develop digital skills. Finally, regarding the AR device used, although AR glasses are a relatively expensive choice, they combine smartphone features with a hands-free operating mode, thus ensuring the industrial task’s fastest and highest quality execution.

____

Solution Summary:

Based on the analysis made in the previous two sections, the following solution is proposed:

The worker captures images of the failed production tool by exploiting AR glasses (which are equipped with vision sensors) and sends them (through IoT protocols or radio communication technologies such as 5G or WiFi) to the remote server for processing by the AI-powered system. This system consists of a Computer Vision/Deep Learning model which extracts the values of the maintenance attributes (MA) from the images of the failed production tool (these are the condition of the paint, dirt, missing parts, etc.). These attribute values are input data on the CBR procedure, which will estimate the maintenance time of the newly entered case. Finally, the AI-powered system sends the output back to the worker’s glasses.

Additional benefits:

- Most AR glasses support WiFi, and thus the connection between them and the local server can be established very quickly, which is a clear advantage.

Possible difficulties:

- This approach has limitations because the technology may start losing track once that barcode is out of view.

- Interference from industrial assets can disturb wireless signals, thus, affecting the reliability of the local network.