Monitor and improve the efficiency of production processes.

Challenge:

Due to the recent increase in production volume, we want to implement a batch of manufacturing system in order to manufacture the product by recipes and improve the raw materials and the finished product.

Along with this change, the aim is to implement a production planning system capable of launching batches automatically and optimize manufacturing times and resources.

Industry Sector:

Global color and specialty chemicals

Challenge classification:

Real-time process monitoring and optimization; Smart planning and scheduling of processes.

Time for Project Completion:

12 months

____

Preliminary Analysis:

Monitoring energy consumption is an important element of production activities, because “energy consumption is one of the most important factors of sustainable machining and it enhances the competitiveness of corporations in terms of lower production costs, higher revenue and greener footprint”, as stated in paper [3]. Likewise, it is important to monitor KPIs. Therefore, we need to develop a solution that will monitor KPIs and energy consumption using appropriate sensors. Data from sensors will be stored in the cloud continuously. Appropriate data processing algorithms should check whether the recorded data is free from errors that would distort the analysis results (ensuring data reliability). Appropriate parameters will be determined on the basis of the recorded data. The calculation of KPIs will be performed by MES. The KPI presentation will be carried out using an application for smartphones / tablets with the possibility of visualization in augmented reality. This is associated with the creation of a digital twin of each monitored workstation. The APS software should be used to create production schedules, while launching production batches will be possible thanks to MES.

Solution Summary:

The proposed solution consists of three layers:

- The layer of monitoring the production process and data storage.

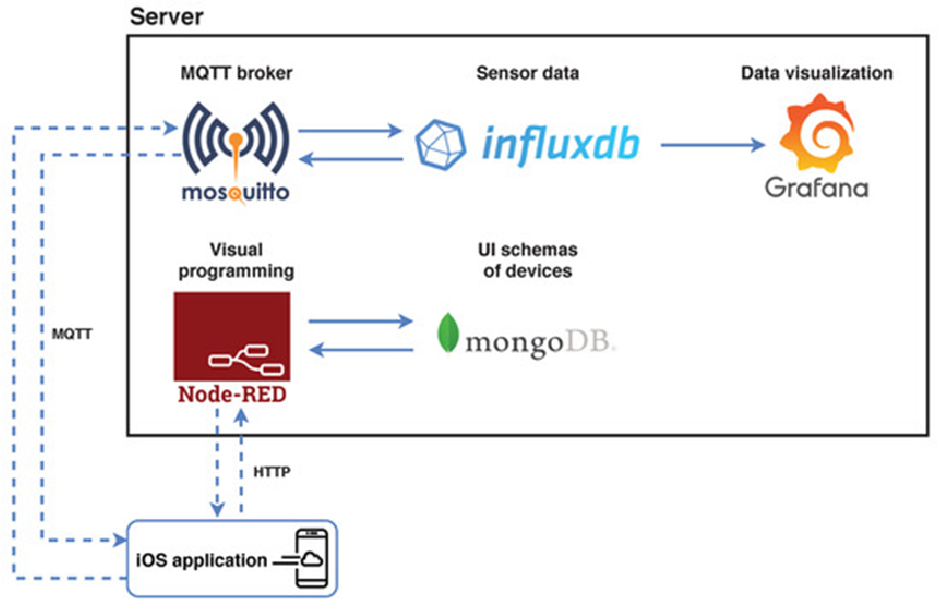

The monitoring layer of the production process should include appropriate sensors monitoring selected parameters at work stations (e.g. temperature, energy consumption). The data recorded by the sensors should be saved on the server (in the cloud). The server part of the solution is shown in Figure 1. As suggested by the authors of paper [4]: “The tools, which are implemented on the server side […] can be run on practically any Linux-based operating system. […] The MQTT broker (mosquitto) runs on the server and serves as the main central point through which all communication between the mobile device and the currently recognized mechatronic system takes place. Messages are sent to the broker using publish-subscribe communication on undefined topics. It is therefore not necessary to define them in advance, but the application that wants to obtain data from the address must be subscribed to receive this type of message.

Node-RED consists of a runtime based on Node.js and a visual editor. The program is created in the browser by dragging functional nodes from the palette into the workspace. Then it is necessary to interconnect these nodes. The application is then deployed to production automatically using the deploy button. Additional nodes can be easily added by installing new nodes created by the programming community. Flows that are created in the workspace can be exported and shared as JSON (JavaScript Object Notation) files.”

Figure 1. Server part of the solution. Source: [4]

- The layer of presentation of monitored parameters and KPIs with the use of augmented reality.

The presentation layer is based on the mobile device and augmented reality application. The authors of the work [4] describe this part of the solution as follows: „The mobile application includes the Wikitude SDK, which provides methods and algorithms for recognizing 3D objects in a real environment using a mobile device camera. A software package in Unity engine format (.unitypackage) is available on the official website of this tool.

Real-world 3D objects are detected by Wikitude by trying to match pre-created references in video streams from mobile device’s camera. Such a prepared reference is called Object Target. It can also be understood as a SLAM map. Object Target is created using input images of a real model (mechatronic device). These are then converted into the so-called Wikitude Object Target Collection, which is saved as a .wto file. The procedure for creating a collection is as follows:

1. Creating photos of an object from different angles (up to 30 photos can be inserted)

2. Convert photos to Wikitude Object Target Collection (.wto)

3. Use of the .wto file in the project in the Unity 3D engine

[…] The generation of a dynamic graphical user interface takes place at the Unity engine level via a definition scheme.”

- The layer of scheduling and production optimization.

One of the commercial software available on the market can be used for production scheduling. An example is Oracle Fusion Cloud Supply Planning with the Production Scheduling module. This solution ensures maximization of production efficiency, optimization of resource use, reduction of costs related to production, increased productivity, and reduction of production waste [5].

Additional benefits:

- Meet performance targets for the entire plant with actionable insights and recommendations based on up-to-date, accurate data. [6]

- Reduce the risk of unplanned shutdowns by receiving early warnings regarding issues you can remedy before they become real problems. [6]

- Besides providing real-time monitoring information, the solution may assist in predictive machine maintenance, once historical data is combined with artificial intelligence and machine learning techniques. [2]

Possible difficulties:

- Problems with communication between machines and the data collection system.

- Difficulty in adapting existing APS systems to the production process.

- Necessity to modify existing production processes.

- Reluctance of the company’s employees against modifying production methods and implementing new technologies.

Sources:

[1] https://www.sciencedirect.com/science/article/pii/S2351978919303865?via%3Dihub

[2] https://link.springer.com/article/10.1007/s00170-020-06245-2

[3] https://www.sciencedirect.com/science/article/pii/S0166361518306808

[4] https://www.mdpi.com/2079-9292/9/8/1272/htm

[5] https://www.oracle.com/scm/manufacturing/[6] https://www.topsoe.com/our-resources/knowledge/our-services/connected-services